Mandrel Manufacturing for a Large OEM10

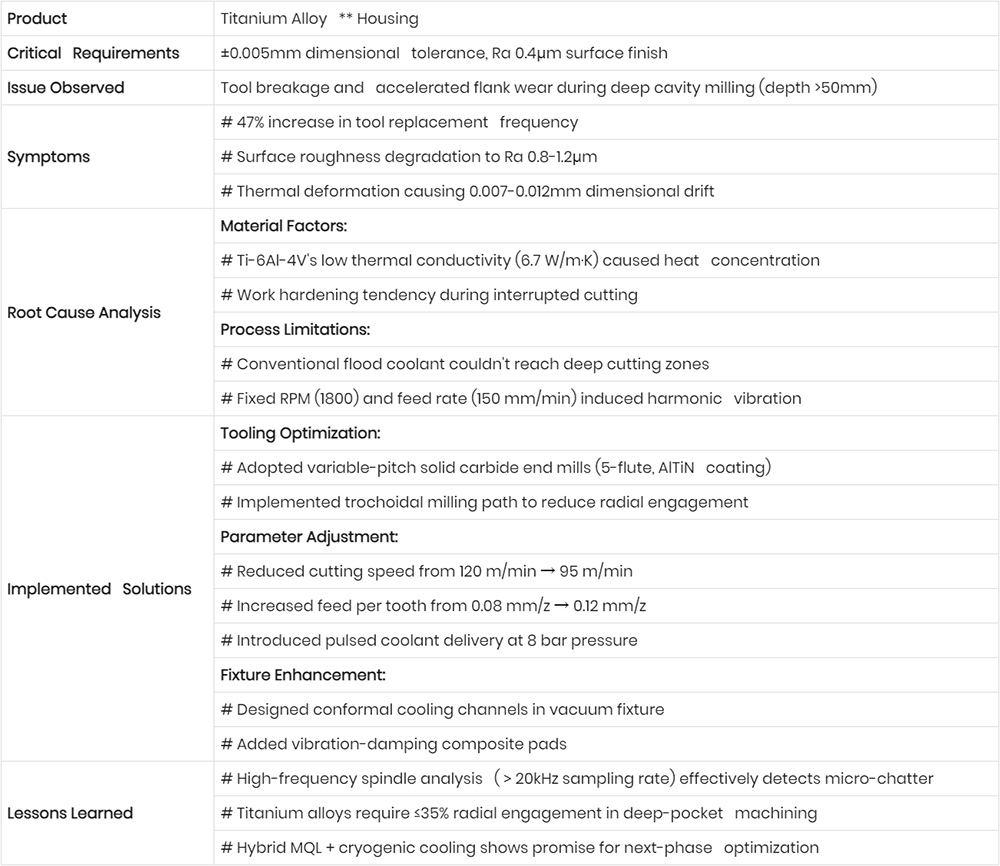

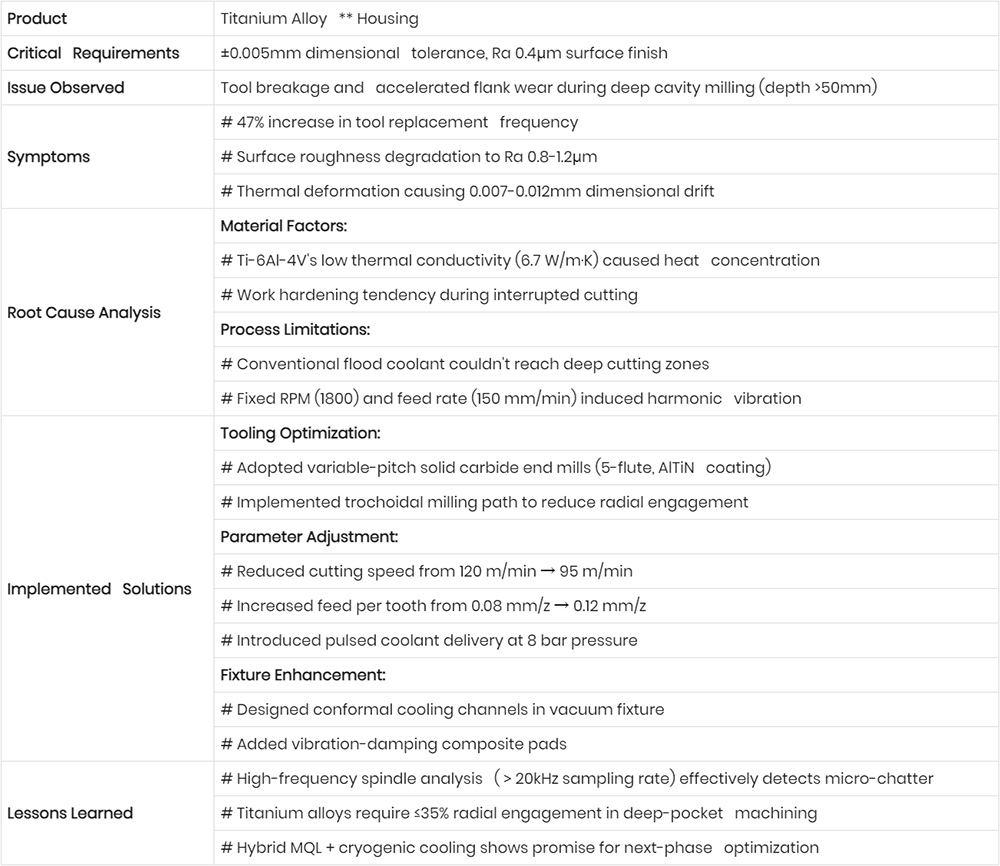

| Product | Titanium Alloy ** Housing |

| Critical Requirements | ±0.005mm dimensional tolerance, Ra 0.4μm surface finish |

| Issue Observed | Tool breakage and accelerated flank wear during deep cavity milling (depth >50mm) |

| Symptoms | # 47% increase in tool replacement frequency |

| # Surface roughness degradation to Ra 0.8-1.2μm |

| # Thermal deformation causing 0.007-0.012mm dimensional drift |

| Root Cause Analysis | Material Factors: |

| # Ti-6Al-4V's low thermal conductivity (6.7 W/m·K) caused heat concentration |

| # Work hardening tendency during interrupted cutting |

| Process Limitations: |

| # Conventional flood coolant couldn't reach deep cutting zones |

| # Fixed RPM (1800) and feed rate (150 mm/min) induced harmonic vibration |

| Implemented Solutions | Tooling Optimization: |

| # Adopted variable-pitch solid carbide end mills (5-flute, AlTiN coating) |

| # Implemented trochoidal milling path to reduce radial engagement |

| Parameter Adjustment: |

| # Reduced cutting speed from 120 m/min → 95 m/min |

| # Increased feed per tooth from 0.08 mm/z → 0.12 mm/z |

| # Introduced pulsed coolant delivery at 8 bar pressure |

| Fixture Enhancement: |

| # Designed conformal cooling channels in vacuum fixture |

| # Added vibration-damping composite pads |

| Lessons Learned | # High-frequency spindle analysis (>20kHz sampling rate) effectively detects micro-chatter |

| # Titanium alloys require ≤35% radial engagement in deep-pocket machining |

| # Hybrid MQL + cryogenic cooling shows promise for next-phase optimization |

Mandrel Manufacturing for a Large OEM9

Mandrel Manufacturing for a Large OEM8